How can we improve the efficiency of cement pipe making machines?

Cement pipe making machine, as the name suggests, is a machine used to make cement pipes, also known as cement pipe making machine and cement pipe making equipment. In some parts of southern China, it is also known as culvert pipe machinery

Cement pipe making machine, as the name suggests, is a machine used to make cement pipes, also known as cement pipe making machine and cement pipe making equipment. In some parts of southern China, it is also known as culvert pipe machinery, mainly consisting of two parts: machinery and molds. According to its structural form, it can be divided into suspended roller type pipe making machine and centrifugal type pipe making machine. How can we improve its work efficiency for this type of engineering building?

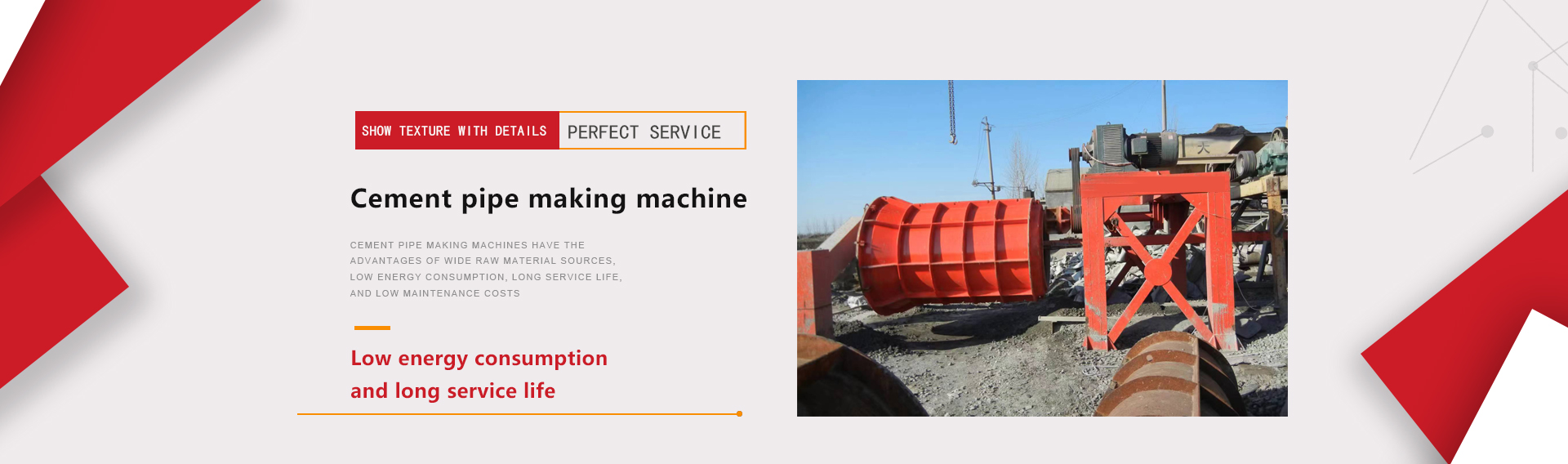

Cement pipe making machine

1. Materials:

The amount and quality of cement play a crucial role. When mixing ingredients, the appropriate use of cement can increase the strength and durability of cement pipes. However, excessive cement can cause the volume expansion and aggravation of silicate during the hardening process, leading to cracking. When the digestion speed of cement is too fast and a large amount of heat is accumulated, the temperature of the product will rise sharply, and the cement pipe making machine will experience significant internal stress, causing the outer surface of the cement pipe to expand and crack. According to experiments, When the cement digestion temperature is greater than 70C and the cement dosage per cubic meter of material exceeds 15% of the total weight, cracks are difficult to prevent and often occur during the static period

2. Manufacturing technology:

When mixing, the water cement ratio should be appropriate to meet the technical requirements of construction. If the water cement ratio is too high during mixing, the cement pipe may experience bleeding phenomenon during the static period, causing the surface of the cement pipe to become soft and cracked. Excessive water evaporates from the inside and outside of the cement pipe during steam maintenance, causing the surface of the cement pipe to become soft, volume to shorten, and cracks to occur. These cracks are scattered sparsely, sometimes forming a layer of 3~4mm thick soft thin shell on the surface, A quiet blow with a hammer will peel and shatter

The production process of the cement pipe making machine should be clean, and flushing work should be done before each shift to ensure that no cement slurry is adsorbed around the operating parts, which will affect the normal operation of the machine. Alright, that's all for our content sharing. Goodbye next time!