Solution Measures for Excessive Oil Temperature in Cement Pipe Making Machine Equipment

Success is a journey, not an endpoint, so as long as everything goes smoothly in the process of moving towards success, it is success.

Success is a journey, not an endpoint, so as long as everything goes smoothly in the process of moving towards success, it is success. Hello everyone, have you been traveling recently? While playing, be sure to pay attention to travel safety and personal protection. Don't slack off on personal protection just because you are temporarily playful. Next, the editor will introduce to you how to choose solutions for high oil temperature in cement pipe making equipment.

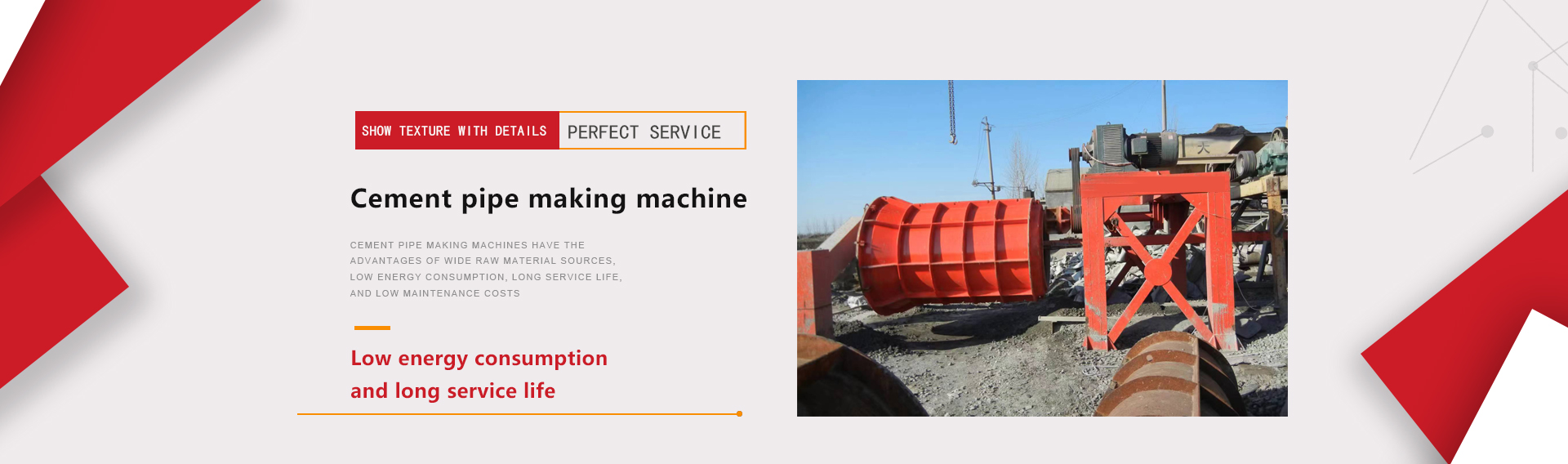

In the use of cement pipe making equipment, if long-term operation occurs, the oil temperature may be too high. How should this problem be solved? Cement pipe making machine equipment, as the name suggests, is the machinery used to make cement pipes, commonly known as cement pipe making machinery and cement pipe making equipment, and also known as culvert pipe machinery in some parts of southern China. The cement pipes produced by cement pipe making equipment have been applied in water supply and drainage projects such as deep wells, municipal drainage, and highways, making great contributions to urban construction in China. During the use of cement pipe making machines, especially in summer, there may be situations where the oil temperature is too high. Today, I will talk to you about how to avoid high oil temperature in cement pipe making machines. Firstly, we need to understand that if the oil temperature of the cement pipe making machine is too high, it will burn out the motor over time. Therefore, it is necessary to understand the measures to prevent excessive oil temperature. Here are a few commonly used methods for everyone: 1. Always pay attention to maintaining the appropriate oil level in the tank to ensure that the oil in the system has sufficient circulating cooling conditions. 2. Correctly select the viscosity of the oil used in the system. If the viscosity is too high, the energy lost when adding oil to flow; If the viscosity is too low, leakage will be added, and both will increase the oil temperature. When the oil deteriorates, it can also cause a decrease in the volumetric power of the cement brick making machine, damage the oil film between the relative moving surfaces, increase resistance, and cause friction loss and addition. These can lead to the heating of the oil, so it is also necessary to maintain the cleanliness of the oil and replace it in a timely manner. 3. When the cement brick making machine system is not in operation, the cement brick making machine must be unloaded. 4. Always pay attention to ensuring that the water in the cooler is sufficient and the pipeline is smooth.

The above content in this article is a general introduction by the editor to the solutions to the high oil temperature in cement pipe making equipment. If you have any other questions, you can leave a message in the comment area below or contact the editor through the contact information below. I hope everyone can gain more or less from the articles I have compiled. Thank you for reading.