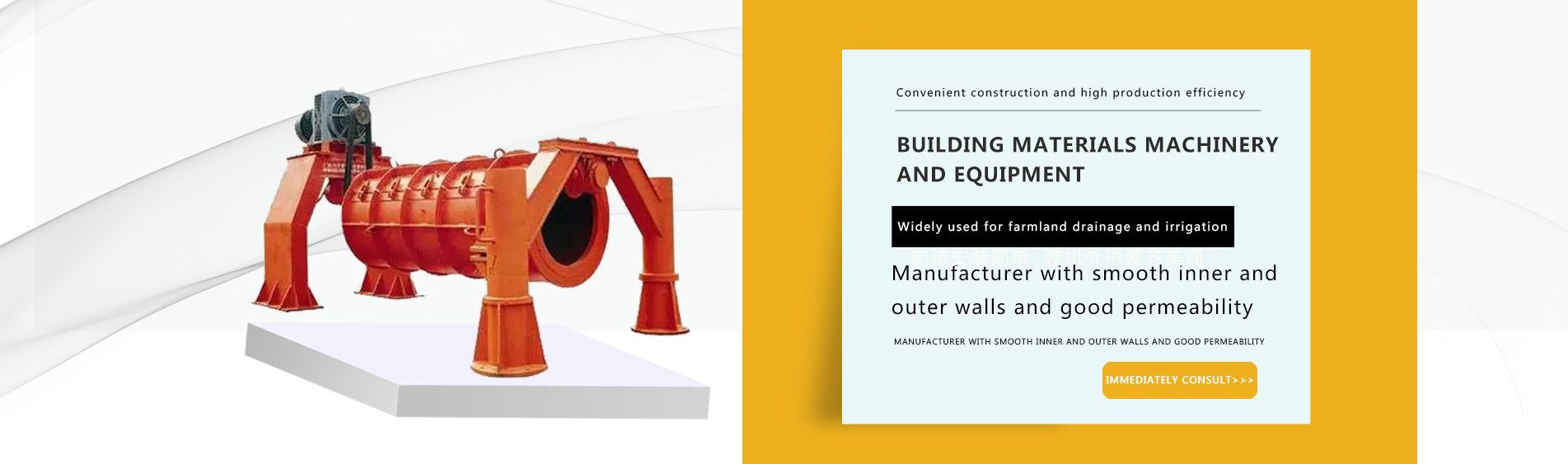

Core mold vibration cement pipe making machine

The core mold vibration pipe making machine is a new process with high mechanization and automation. Although it started late, it has been increasingly valued and favored by the pipe making industry due to its advantages. Process principle of core mold vibration equipment

Details

The core mold vibration pipe making machine is a new process with high mechanization and automation. Although it started late, it has been increasingly valued and favored by the pipe making industry due to its advantages. Process principle of core mold vibration equipment:

(1) The underground closed vertical forming of the core mold vibration pipe making machine, with ground control, has changed various unfavorable factors of centrifugal and suspended roller processes in horizontal production on the ground. The production and working environment have been greatly changed, and the labor intensity of workers is low, which is conducive to production;

(2) Adopting dry and hard concrete as a dry production process, with zero slump, low water cement ratio, and high frequency vibration, the concrete has high strength;

(3) Due to vertical production, the concrete does not need to completely pass through the steel reinforcement framework from the inside out when placing raw materials, as is the case with centrifugal and suspended roller processes in horizontal production. Therefore, the concrete material is less affected by the pitch of the steel reinforcement. Therefore, when reinforcing steel and meeting relevant conditions, fine diameter steel bars can be selected as much as possible to reduce the width of cracks or delay the occurrence of cracks, which can adapt to the production of small pitch and dense reinforcement;

(4) Due to vertical production, the core mold vibration equipment socket is placed at the bottom, making it suitable for the production of socket and groove pipes, changing the process factor of low socket strength in horizontal production.